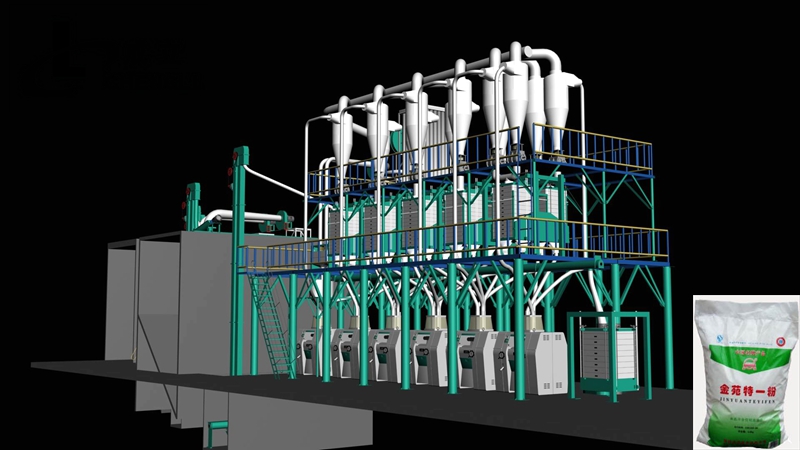

(1). Technology of cleaning parts: twice screening(1set vibrating sieve and 1set rotary sieve), twice de-stoner(1set de- stoner and 1set washer stoner), twice scouring(1 set horizontal scourer), once washing(1set washer stoner) and twice air separation (magnetic separator).

(2).Technology of flour milling parts: four sets of 6F 2250 roller mill and six sets of 6F 2240 roller mill, consists of 4B ( breaking system ), 4R ( reduction system) and 1S(Scratch System).

(3)Flour extraction rate: 70-75%, according the consummer's requirments,equipment can be adjusted to produce special precise flour,special flour or other flour for special use.

(4). Capacity: 50 ton of wheat per 24 hours

(5). Power supply: about 137 kw/ 380V, 50 Hz

(6). Power consumption: 60 kwh in processing one ton of wheat

(7). Workshop style and dimension: triangle framed workshop with 11m long, 6.2m wide and 7m under the beam(11x6.2x7m)

(8). Packing details: packed in one 40 GP container